Moving Pringles Can Final

Objective: I wanted to create a machine that would raise the pringles chips to meet the users hand to avoid them having to reach down the can to get the next chip.

Second Iteration

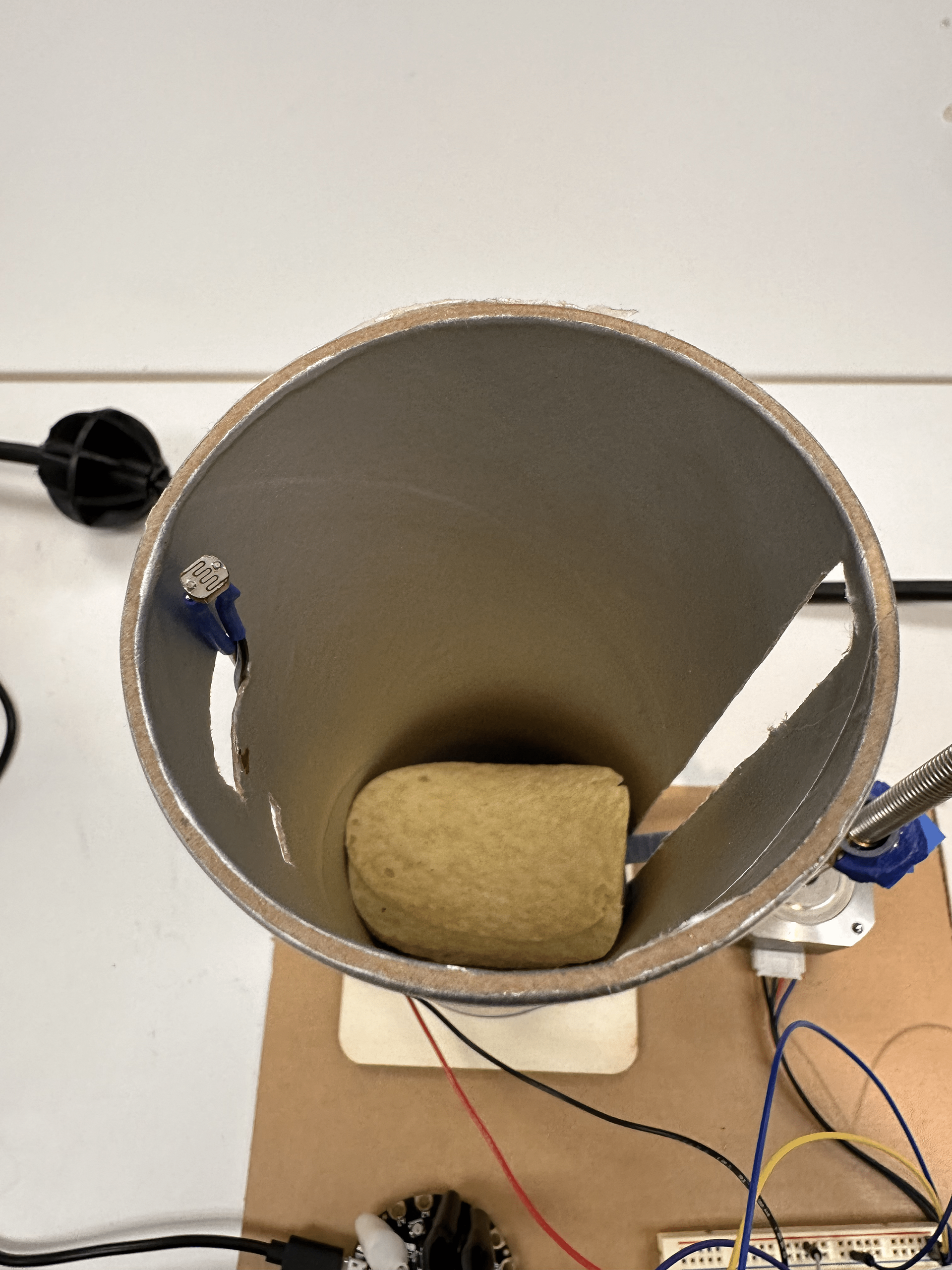

In my second iteration for the final project, I wanted to use a light sensor that would sense when the user's hand enters the can and when it exits. When the user places their hand in the can, it will raise the chips to meet their hand and when they remove their hand the machine will stop. When the user is done eating the chips and places the cap back on, the machine will move the platform back down.

Process

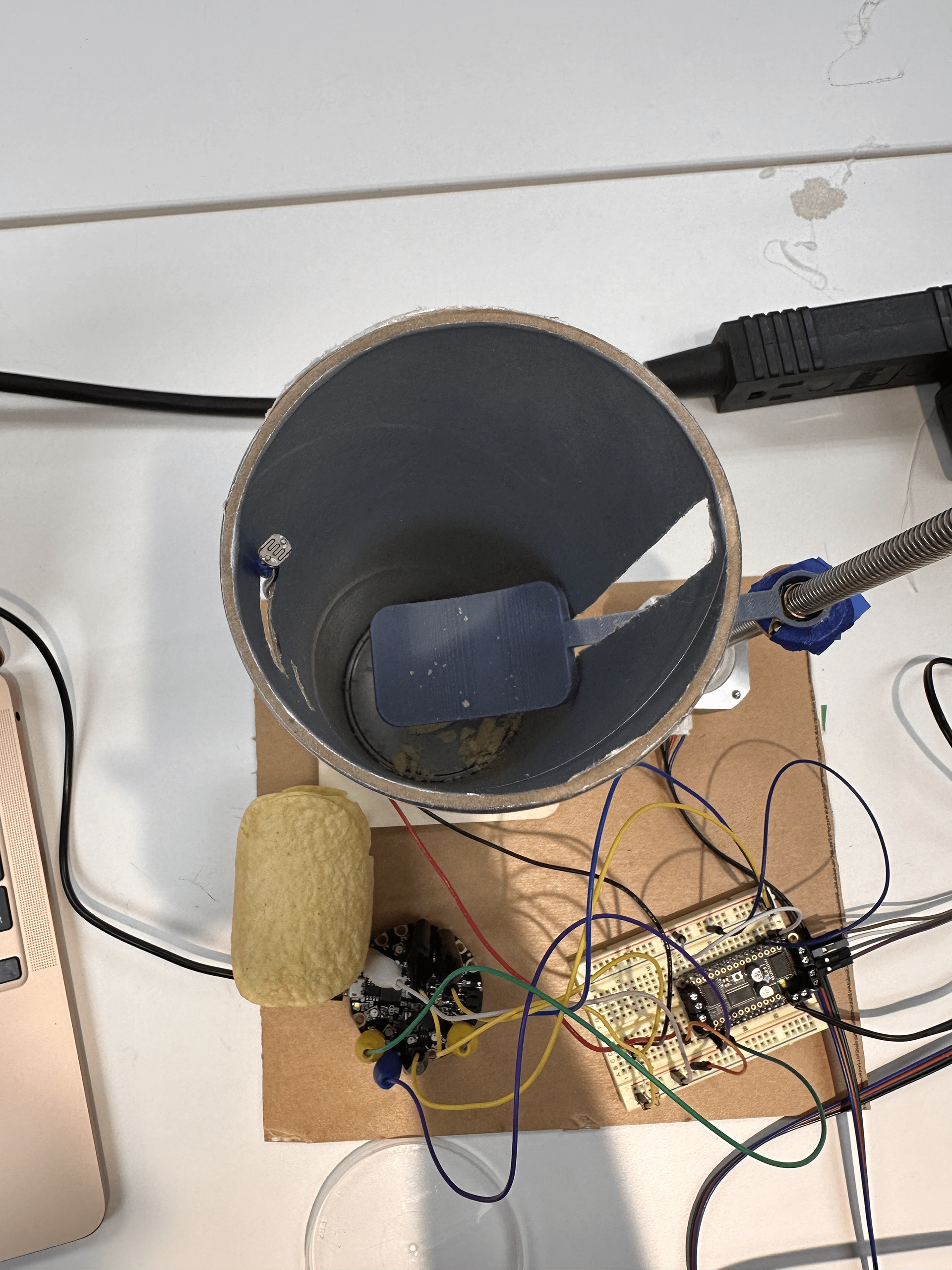

Unlike my first iteration, I had to use a breadboard to connect all the components together. In the beginning, I used a smaller breadboard to connect the light sensor to my circuit and the featherwing was separate. This made my project be very cluttered.

However, I could simply it by using a bigger breadboard and place the featherwing into the breadboard. Now, my breadboard connects the stepper motor and my light sensor to my circuit.

The light sensor by default is pretty short so I need to extend it by using wires and have the output be pins to stick into the breadboard. I wanted the light sensor to be at the top of the can so it can detect when someone puts their hand into the can.

Inside the can is the 3D printed lever I created in Onshape to raise the chips

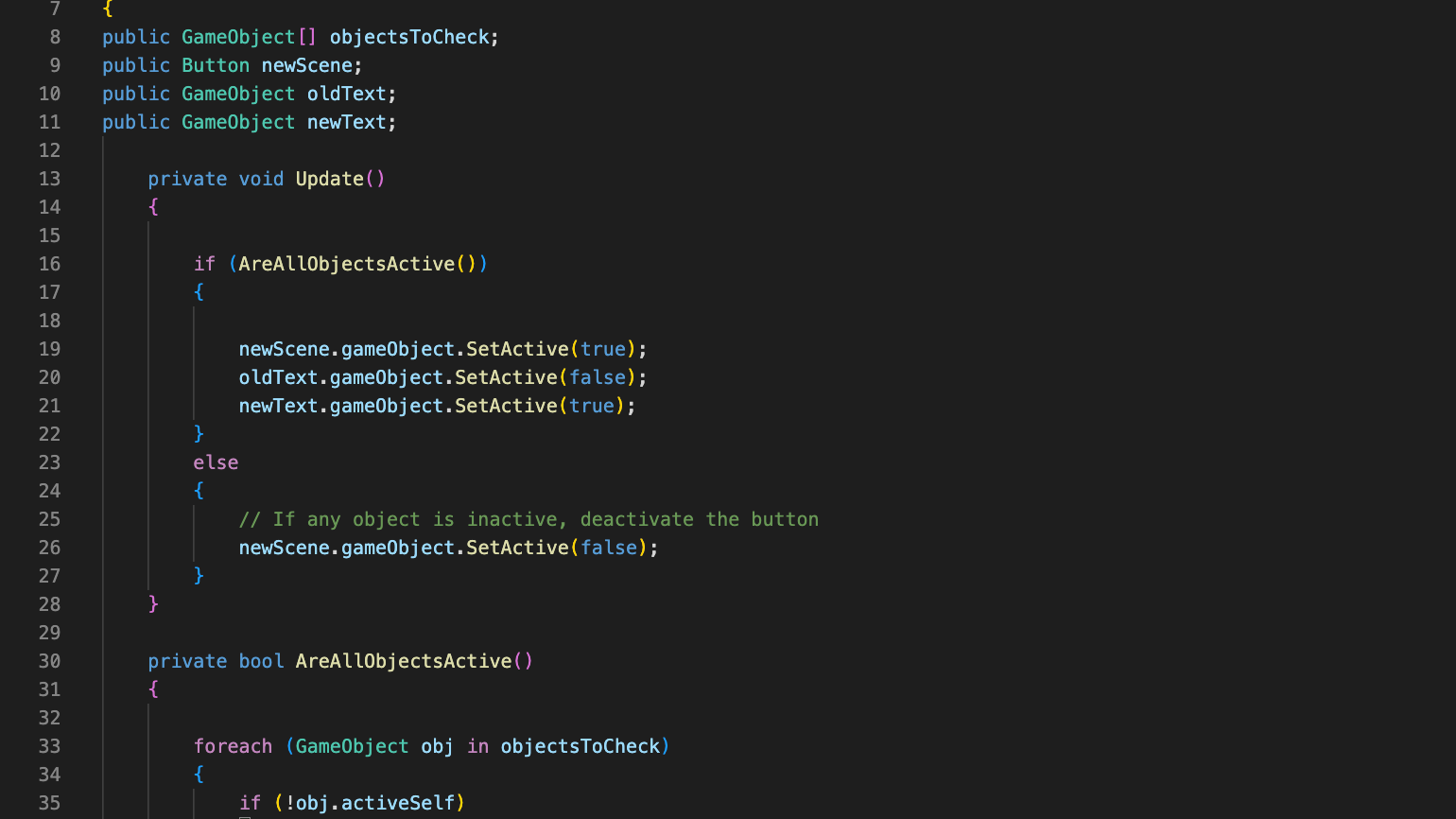

Code

For the code, I created ranges for the light sensor and depending on its range it would either raise or lower the chips. One difficulty I had was that the range for lowering the chips constantly changed because of the light and positioning of can. The range for raising the chips stays the same.

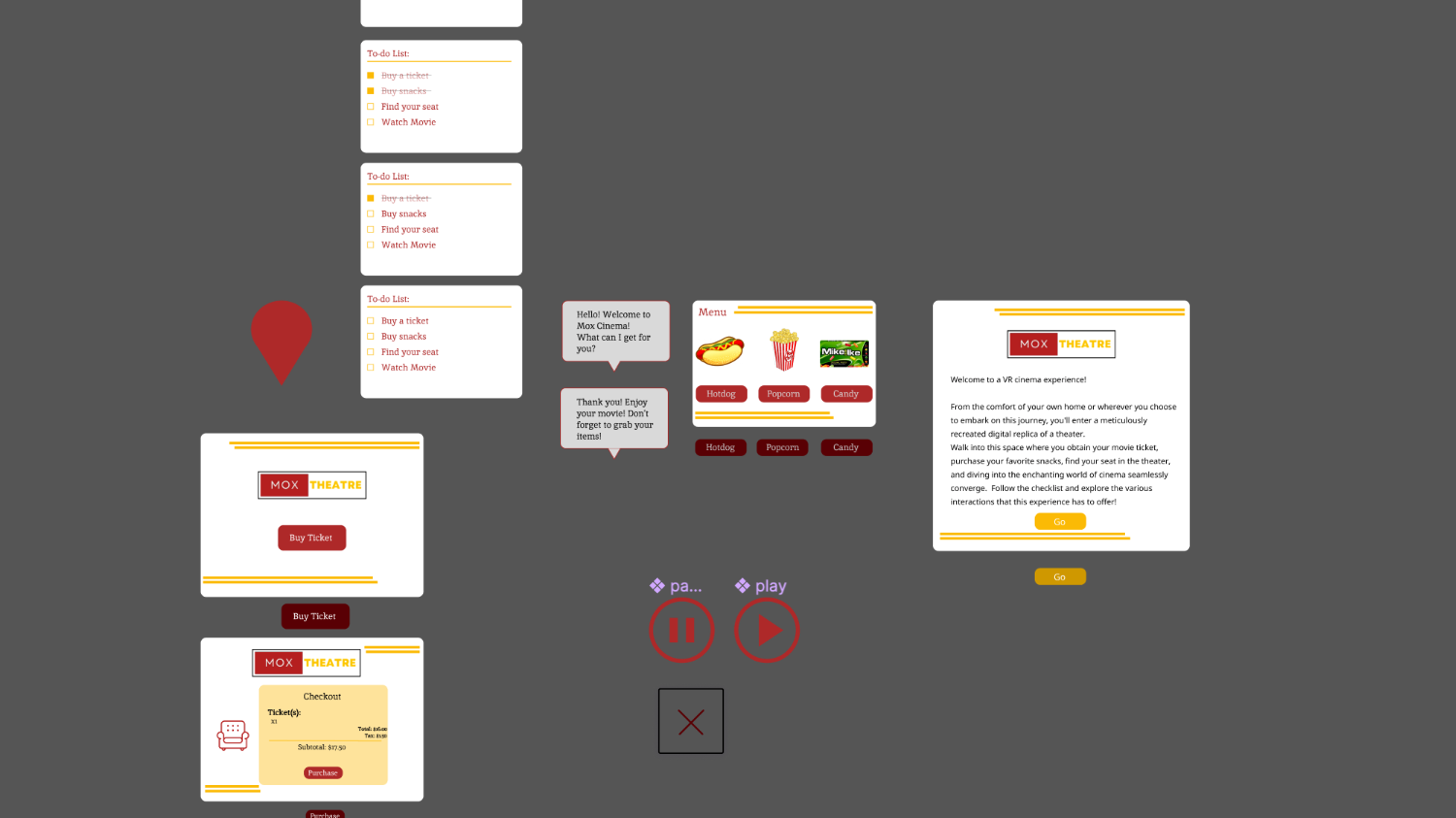

Project 2

Moving Pringles Can

For my project, I wanted to create a machine that would raise the chips to meet the users hand to avoid them having to reach down the can to get the next chip.

Process

I designed and 3D printed the handle to hold the chips and connect it to the steppe motor. Through my first run through of printing out the handle, I measured the diameter of the stepper motor and I put that measure in Onshore not realizing it was asking for the radius. Therefore, the circle piece was way too large and I had to reprint it with the correct measurement.

I created a slit in the side of the Pringles can so that the handle can move up and down and I cut out two squares in the back to connect the switch. In my first iteration, I created the slit too uneven and the cutout squares way too low for the switch. I wanted the switch to be right at the top to simulate an experience where you put your hand in the can and it will trigger the switch.

I used a featherwing to connect the stepper motor to my microcontroller. I had to switches to control the stepper motor. If you hold the one inside the can it will allow the motor to move up and the outside switch allows you to move it back down.

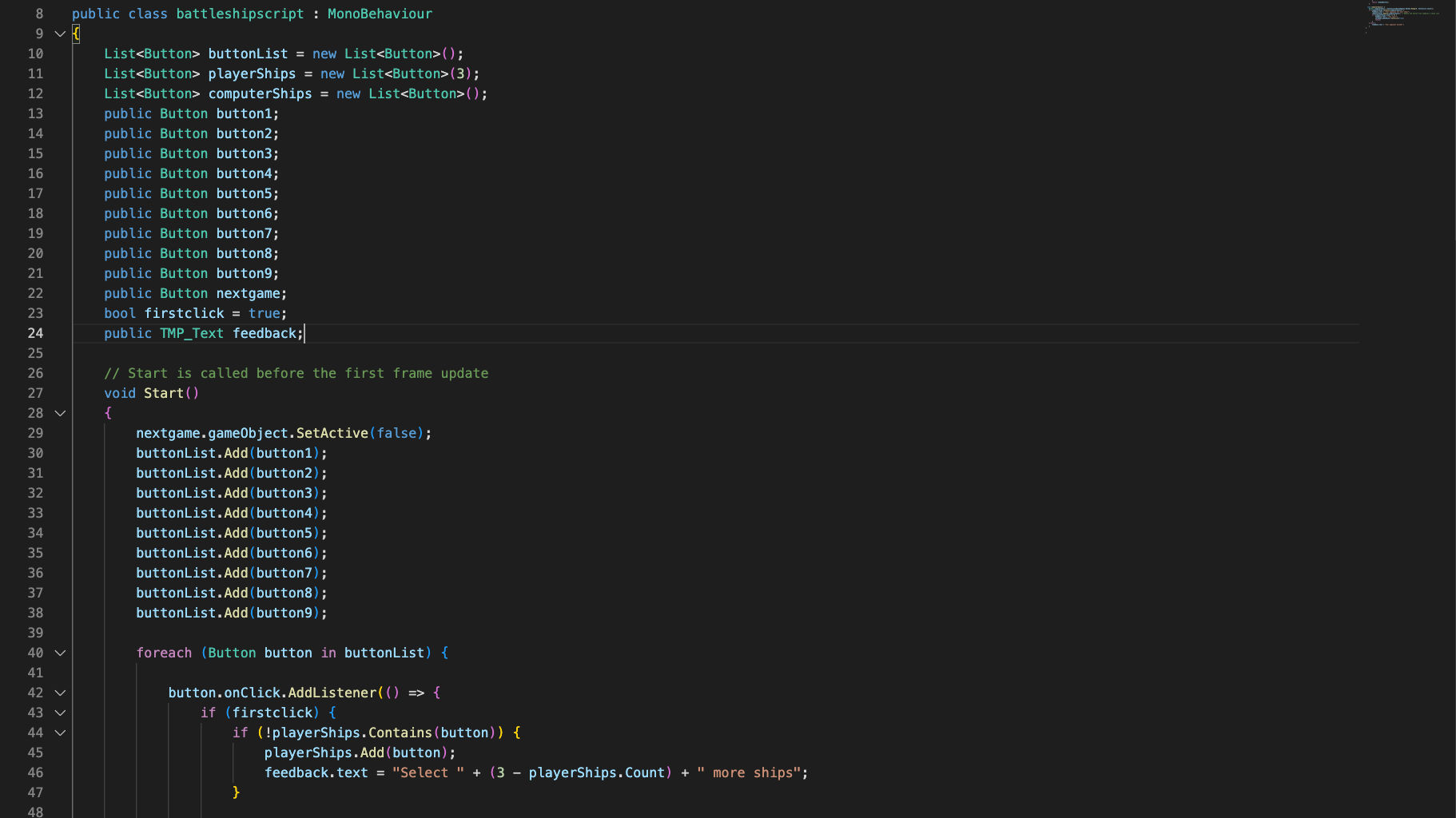

Script